The dotting technique is the signature element of putting copper pieces together regardless of the object. If you can manage to make a decent dot of phos on a piece of copper the rest will come together simply enough. It entirely depends upon recognizing when the copper sheet, tube, or wire is at the right temperature to accept the phos. Metal too hot and the phos runs everywhere. Metal too cold and the phos beads up and does not adhere. If the temperature is just right you will have a raised BB sized dot of phos ready to help you put things together. It takes practice, and it doesn't make sense to try to make anything until you can make a halfway decent dot. Some people get it in 15 or 20 minutes and some longer, but its not rocket science and if you practice you will get it right because the metal will be your teacher.

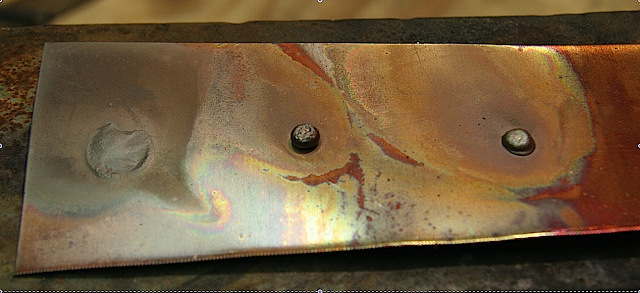

Once again. The metal knows nothing. It responds to the heat and that is all. We control the metal by controlling the heat. If your dot spreads out over the sheet metal the sheet metal is too hot. If it rolls off like a BB the metal is too cold. If it stands up with a little melt around the base of it like a scoop of ice cream on a warm sidewalk then you've got it.

Here we go. With the lit torch in one hand and a stick of phos in the other bring the torch to the surface of the sheet copper.

I am right handed, and I hold the torch in my right hand with no glove. I hold the brazing rod in my left hand with a glove, because the heat reflects up toward my left hand. You will soon work out what works for you.

With the flame tip not quite touching the metal, briefly pre-heat the surface. then bring the brazing rod to the flame and melt off a little dot.

There: that's all there is to it. The metal gets a "grayish" look when it is about the right temperature. When the copper starts to glow it is way too hot, and it is way to hot long before it starts to glow. Experiment: get it way too hot. . . see what happens. Melt a dot off on cold sheet metal. . . see what happens. Once you can make a serviceable dot you are on your way. The most common mistake is soaking the metal with heat. You have no control when the metal is soaked with heat. Get in. Get out. If the metal is too hot let it cool, or cool it with the spray bottle.

Now let's make something.

Once again. The metal knows nothing. It responds to the heat and that is all. We control the metal by controlling the heat. If your dot spreads out over the sheet metal the sheet metal is too hot. If it rolls off like a BB the metal is too cold. If it stands up with a little melt around the base of it like a scoop of ice cream on a warm sidewalk then you've got it.

Here we go. With the lit torch in one hand and a stick of phos in the other bring the torch to the surface of the sheet copper.

I am right handed, and I hold the torch in my right hand with no glove. I hold the brazing rod in my left hand with a glove, because the heat reflects up toward my left hand. You will soon work out what works for you.

With the flame tip not quite touching the metal, briefly pre-heat the surface. then bring the brazing rod to the flame and melt off a little dot.

There: that's all there is to it. The metal gets a "grayish" look when it is about the right temperature. When the copper starts to glow it is way too hot, and it is way to hot long before it starts to glow. Experiment: get it way too hot. . . see what happens. Melt a dot off on cold sheet metal. . . see what happens. Once you can make a serviceable dot you are on your way. The most common mistake is soaking the metal with heat. You have no control when the metal is soaked with heat. Get in. Get out. If the metal is too hot let it cool, or cool it with the spray bottle.

Now let's make something.

|

| Too Hot Too Cold Just Right |

No comments:

Post a Comment